One of the First.

One of the Best.

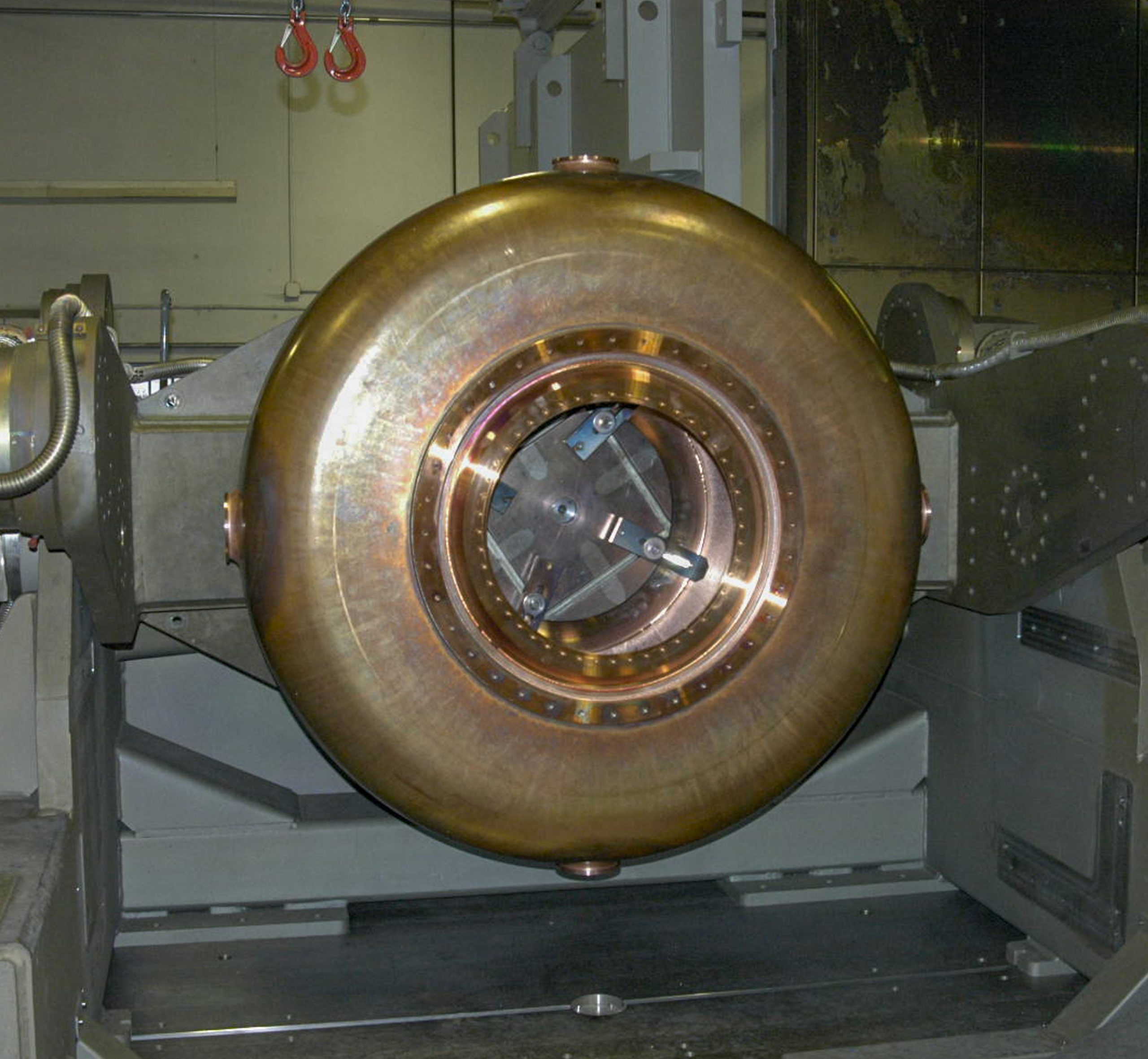

Electron beam welding at Applied Fusion

Applied Fusion was one of the first shops in the U.S. to integrate electron beam welding into the job shop industry. When the semiconductor industry was born, we were ready. We immediately assisted engineers with new welding methods that allowed designers to create components that were previously impossible.

Today, we provide electron beam welding services for all industries that require high-end, highly reliable welding and brazing requirements. We commonly work with all alloys including Inconel and Hastelloy, and refractory metals such as Titanium, Tantalum, Molybdenum, Niobium and Tungsten.

Our skilled e-beam welding team has over a century of combined experience. They work in unison, openly sharing techniques and constantly taking on new challenges while developing new applications and fine tuning older processes. Because Applied Fusion has full, complete, in-house manufacturing capabilities, designing and machining custom tooling and fixturing to complement and streamline throughput is a daily activity, which saves customers both time and money. Our e-beam welding facility is truly the gem and the heart and soul of our company. It has earned worldwide recognition as a competent and efficient shop for the major industries that demand our services.

Our Expert Team

We have an expert Inspection and Quality Control team at Applied Fusion, fully trained to ISO Standards. Our Inspection Department employees have been with the company for years and understand today’s global standards. Supporting this team is our in-house ISO 9001:2008 specialist, who is in constant sync with our production, overseeing and maintaining our Quality Manual

Our metallurgical services

We offer e-beam welding services with an in-house, highly experienced metallurgist/welding engineer. He and others are always available to work with customers to help assist in material selection, address metallurgy issues, joint design, stress analysis and anything else related to the vast foreign world of welding metallurgy. This value-added service lets customers keep their project in one facility and to talk with us directly about all aspects, from inception to final results. Upon customer request, we can provide cross-sectioned coupons along with micrographs to expose penetration and weld quality, working closely with other testing laboratories that are in close proximity in case there is a need for additional non-destructive and destructive testing.

Our E-Beam specialties

We specialize in vacuum components and pressure vessels, and we have leak checking facilities in various areas to provide immediate leak teasing and flow testing services. Our technicians have extensive knowledge in vacuum and pressure technology and continuously keep our equipment calibrated and maintained. These services are used throughout the manufacturing processes of products and are certified upon completion. Our machine shop is always available to fabricate any tooling that may be required to perform leak check and flow check tasks safely and efficiently.